Fresnel lens

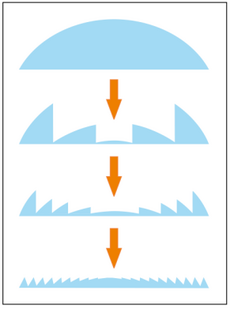

A Fresnel lens is an optical component used as an alternative to a conventional lens due to it being lighter and more cost-effective. Since the refractive power of a lens is in the optical interfaces - the lens surfaces - in a Fresnel lens the optical material is removed as much as possible while maintaining the surface curvature (Figure 1). [1]

A Fresnel lens is made of several concentric grooves etched into a substrate such as plastic. Due to their characteristics, this type of lens is capable of focusing light similar to a conventional lens while being physically narrow in profile. [2]

Fresnel lenses have a variety of applications due to their thin, lightweight construction, good light gathering ability, and availability in different sizes (Figure 2). They are often used in light gathering applications (e.g. condenser systems or emitter/detector setups), as magnifiers or projection lenses in illumination systems, and image formulation. [2]

In virtual reality (VR) technology, they are used in head-mounted displays (HMDs), mainly those in the high-end of the spectrum, where weight, thickness, and cost are essential parameters to take into account. [3]

Theory overview of a Fresnel lens[edit]

The principle behind a Fresnel lens is that the direction of propagation of light is not affected within a medium unless scattered. However, light rays deviate at the surfaces of a medium. This means that the majority of the material in the center of a lens only increases its weight and absorption within the system. [2][3]

A classical lens can become very heavy and expensive if the curvature and radius are sufficiently large. A Fresnel lens solves this since the light bending is essentially determined by the angle at the surface of the lens. The Fresnel lens has the same curvature at each point of incidence but is not as thick as a regular lens, achieving this by segmenting the classic lens and bringing together small segments of the right curvature. Almost every point in the Fresnel lens has the same curvature as a corresponding point in a classical lens. [3]

Depending on the application, a Fresnel lens can have a better focusing performance than a conventional optical lens. Also, a Fresnel lens with a high groove density allows high-quality images, while low groove density provides better efficiency, in the case of light gathering applications. [2]

Slope and draft[edit]

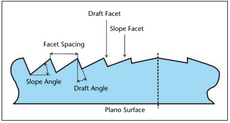

When compressing the lens surface into a plano surface there is the need for a finite prism pitch, and both a slope angle and draft component (Figure 3). The slope angle is responsible for refracting the light in the prescribed manner while the draft component “for the normal refractive lens design is optically inactive but necessary to return the surface profile ”back to the plane“. [1]

Focal length and f-number[edit]

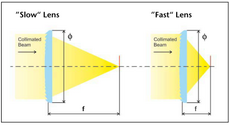

The focal length and f-number are other parameters used to specify a Fresnel lens. According to Davis and Kühnlenz (2017), typically, “the focal length [f] is the distance from the lens to where an idealized collimated input beam converges to a point (Figure 4). More specifically, for a lens with prism facets on one side and a flat plano surface on the other side, the effective-focal-length is very closely approximated as the distance from the prism surface of the lens to the focal point. Also, it is commonplace to define the back-focal-length as the distance from the plano side of the lens to the focal point.” [1]

The other parameter - the f-number - is the ratio of the focal length to the clear aperture diameter of the lens (φ). Alternatively, the f-number is referred to as the “speed” of the lens: when the f-number is low, the lens will concentrate the light faster, while a lens with a higher f-number will concentrate light slower. [1]

Collimating and converging Fresnel lenses[edit]

There are two types of Fresnel lenses based on how they affect light: collimating and converging lenses. A collimating lens converts a light source to a beam of parallel light (Figure 5). On the other hand, a concentrating lens converts parallel light rays to a focal point, therefore concentrating them (Figure 6). Davis and Kühnlenz (2017) also explain that “a grooves-out design directs the facets towards the side of the collimated beam (also called the infinite conjugate or the long conjugate) and a grooves-in design orients the facets towards the focal point (also called the short conjugate). (The) selection of the facing direction of the grooves, especially for fast lenses, plays an important role in determining the lens transmission efficiency.” [1]

Disadvantages[edit]

One of the main disadvantages of using a Fresnel lens is the lost light due to incidence on the draft facet. A way to minimize this would be to make the facet perfectly vertical. However, in reality, when manufacturing this type of lens, the draft facet requires at least a few degrees of tilt in order to facilitate mold release. Loss of light can be minimized by a design which locates the draft facet within the “shadow” of a slope facet. While this option keeps a high total transmission efficiency, luminance is reduced. [1]

The grooves of the Fresnel lens have also to be taken into consideration when applying the lens as a component of a display application or any application in which the lens is looked-through. To minimize the impact of the grooves, the lens has to have a facet pitch less than or equal to the resolving power of the human eye, making the prisms smaller than can be seen. [1]

Applications[edit]

Fresnel lenses have a myriad of applications that can be condensed in three main categories:

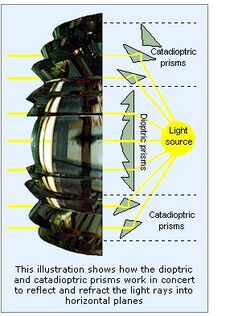

Light collimation: since a Fresnel lens can collimate a light source easily, it can be used in situations when this is required like lighthouses (Figure 7). [2]

Light collection: this is one of the most common applications for this type of lens. It is usual in solar applications, to concentrate light onto a photovoltaic cell or to heat a surface. [2]

Magnification: a Fresnel lens can be used as a magnifier or projection lens. [2] In general, Fresnel lenses are optimal for applications requiring thin, lightweight, and inexpensive lens elements. This type of lens is not a recent technology, but its use has increased due to improvements in manufacturing techniques and materials. [2]

History of Fresnel lenses[edit]

The Fresnel lenses were popularized by the French physicist Augustin-Jean Fresnel (1788-1827), He was not the first to conceptualize a Fresnel lens but by integrating it into lighthouses he made the lens ubiquitous. [2]

In lighthouses, before Fresnel lenses, they required very a large lens to focus the light from the lighthouse into a beam. Using the new design, the lens could be thinner, lighter and cheaper. [3]

In the 19th century, shipping was increasing throughout the world and there was the need for an optical system that could cast light many miles out to sea to provide advanced warning of danger or safe harbor. Therefore, the French Government commissioned Fresnel to develop an improved lighting system for French lighthouses. [4]

He designed a barrel-shaped array of lenses that encircled the light source. This design dramatically increased the light output when compared to previous lighthouse systems. Another benefit was the lens’ modular construction. Terry Pepper writes that “a Fresnel lens could be built in one location, disassembled and easily shipped in multiple small sections, making transportation and re-assembly in the tight confines of a lantern room significantly easier than would have been the case with an optic made up of few huge glass components. Also, the modular nature of the design lent itself to easy modification of characteristic through the insertion of bulls-eye panels and changes in a lenses rotation speed.” Due to these advantages, Fresnel’s design was eventually adopted worldwide as the standard lighthouse lens. [4]

Initially, Fresnel lenses were manufactured by grinding and polishing glass by hand. This was a tedious process and, eventually, molten glass was poured into a mold to produce these lenses. In the 20th century, the development of optical-quality plastics and injection-molding technology facilitated the manufacturing process, making the use of Fresnel lenses in many industrial and commercial applications practical. A Fresnel lens can be manufactured from different substrates such as acrylic, polycarbonate, or vinyl. [2]

Fresnel Lens VR[edit]

With the popularization of VR and the commercialization of VR HMDs to the general public, Fresnel lenses have been integrated into some headsets to try to reduce their weight, thickness, and cost. The type of lens used in a VR headset is generally a factor that is overlooked when determining the HDMs’ quality. Virtual reality headset lenses are important to help the viewer focus on the display’s images at close distances. [3][5]

The standard lens used in almost all mobile VR headsets is a singlet. Compared to a Fresnel lens, singlets are thicker, heavier, and curved. High-end headsets like the HTC Vive use Fresnel lenses. The Oculus Rift CV1 has hybrid Fresnel lenses. [5][6]

In 2017, Wearality showed a prototype of a new Fresnel lens. The company already had developed a unique Fresnel lens for VR headsets, the Wearality Sky. The new lens is extremely thin and light, even when compared to those used in the high-end VR HMDs. [7]

The use of Fresnel lenses in VR is not without setbacks. Boger (2015) explains that “the main problem is what happens when light hits the ridges, those peaks in the lens that do not correspond to actual curvature in the original lens. When light hits these points it is scatted, and scattered light in an optical system reduces contrast. Thus, you will often see that a Fresnel lens produces a more “milky” image with lower contrast. The second problem is a more technical one – it is more difficult to simulate a Fresnel lens in an optical design software.” Creating a lens with many segments will lead to a sharper image, but light will be lost. Lenses with fewer segments will lose less light but the image produce will not be as sharp. [3][6]

In the HTC Vive, the Fresnel lenses can occasionally show bright, concentric circles that can be distracting to the user. On the Oculus Rift, the hybrid Fresnel lenses can have the side effect of generating god rays. [8]

References[edit]

- ↑ Jump up to: 1.0 1.1 1.2 1.3 1.4 1.5 1.6 Davis, A. and Kühnlenz, F. (2017). Optical design using Fresnel lenses: basic principles and some practical examples. Optik & Photonik, 4: 52-55

- ↑ Jump up to: 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 Edmund Optics. Advantages of Fresnel lenses Retrieved from https://www.edmundoptics.com/resources/application-notes/optics/advantages-of-fresnel-lenses/

- ↑ Jump up to: 3.0 3.1 3.2 3.3 3.4 3.5 Boger, Y. (2015). The promise and perils of using Fresnel lenses. Retrieved from http://vrguy.blogspot.pt/2015/08/the-promise-and-perils-of-using-fresnel.html

- ↑ Jump up to: 4.0 4.1 Terry Pepper. The incredible Fresnel lens: A brief history and technical explanation. Retrieved from http://www.terrypepper.com/lights/closeups/illumination/fresnel/fresnel.htm

- ↑ Jump up to: 5.0 5.1 Visbit Inc. A guide to 360º virtual reality: part 2 - headsets. Retrieved from https://medium.com/visbit/a-guide-to-360%C2%BA-virtual-reality-part-2-headsets-5167a0d0870f

- ↑ Jump up to: 6.0 6.1 VR Lens Lab (2016). How lenses for virtual reality headsets work. Retrieved from https://vr-lens-lab.com/lenses-for-virtual-reality-headsets/

- ↑ He, F. (2017). New Fresnel lens from Wearality is thinner than a quarter. Retrieved from https://www.roadtovr.com/new-fresnel-lens-wearality-thinner-quarter/

- ↑ Hutchinson, L. (2016). For this gadgethead, the HTC Vive may force my Oculus Rift to collect dust. Retrieved from https://arstechnica.com/gaming/2016/05/why-vive-has-won-the-early-vr-race-in-my-house/2/